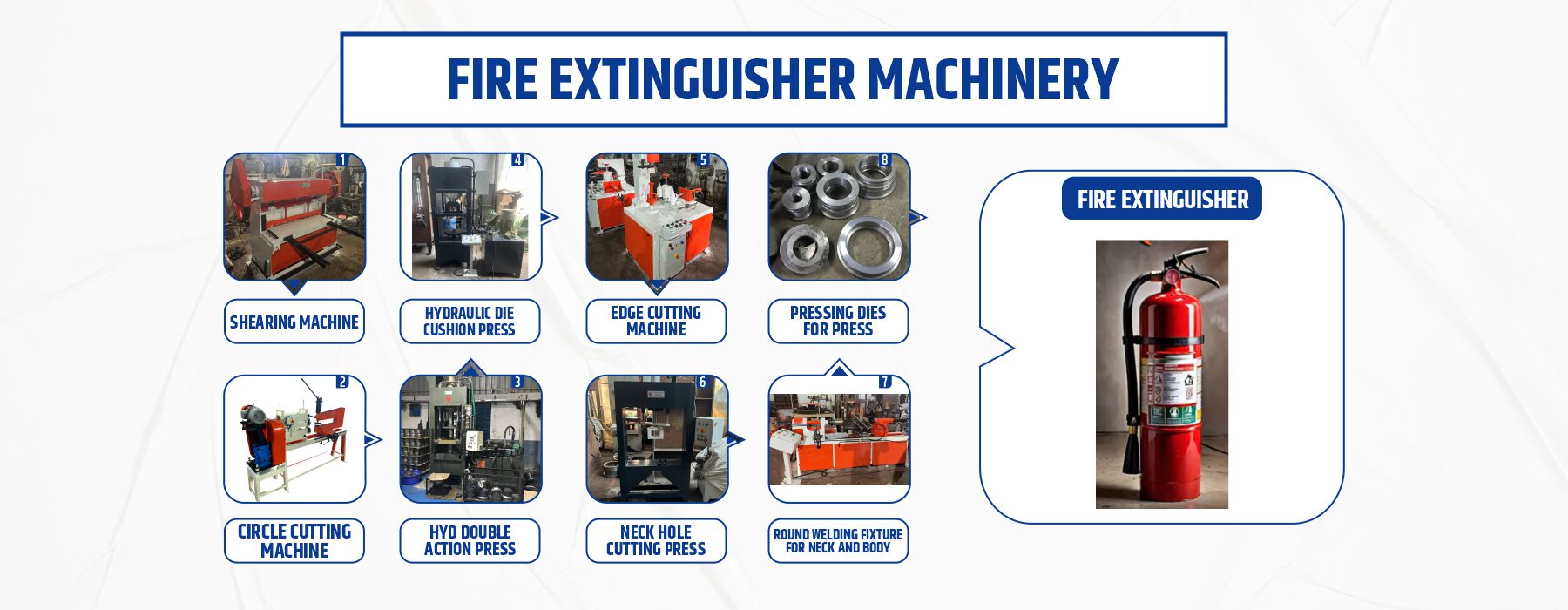

Fire Extinguisher Bottle Plant From Start to Finish

We follow a streamlined and precise process to manufacture high-quality canisters that meet global standards. Each step in our process is designed to ensure durability, efficiency, and superior craftsmanship.

The process begins with cutting metal sheets into required sizes using a Shearing Machine. This ensures precise dimensions for further processing.

The cut sheets are then shaped into circular blanks using a Circle Cutting Machine. These blanks will form the base structure of the extinguisher bottle.

Deep Drawing Fixture

The circular blanks undergo a Hydraulic Double Action Press, which stretches the metal into a deep cylindrical shape without breaking the material integrity.

Hydraulic Die Cushion Machine

To further shape and refine the cylindrical structure, a Hydraulic Die Cushion Press is used. This press ensures uniform thickness and proper shaping of the extinguisher body.

Learn More

Edge Cutting Machine

The top edges of the cylinder are trimmed using an Edge Cutting Machine to ensure smooth and even finishing.

Learn More

Neck Hole Cutting Machine

A Neck Hole Cutting Press is used to create the required opening at the top, where the nozzle and valve assembly will be installed.

Learn More

Round Welding Fixture For Neck & Body

The extinguisher body undergoes a Round Welding Fixture for Neck and Body. This step ensures a strong and leak-proof joint between different metal parts.

Learn More

Pressing Dies for Final Shaping

The body is further refined using Pressing Dies for Press, which give the extinguisher its final shape, improving durability and structural strength.