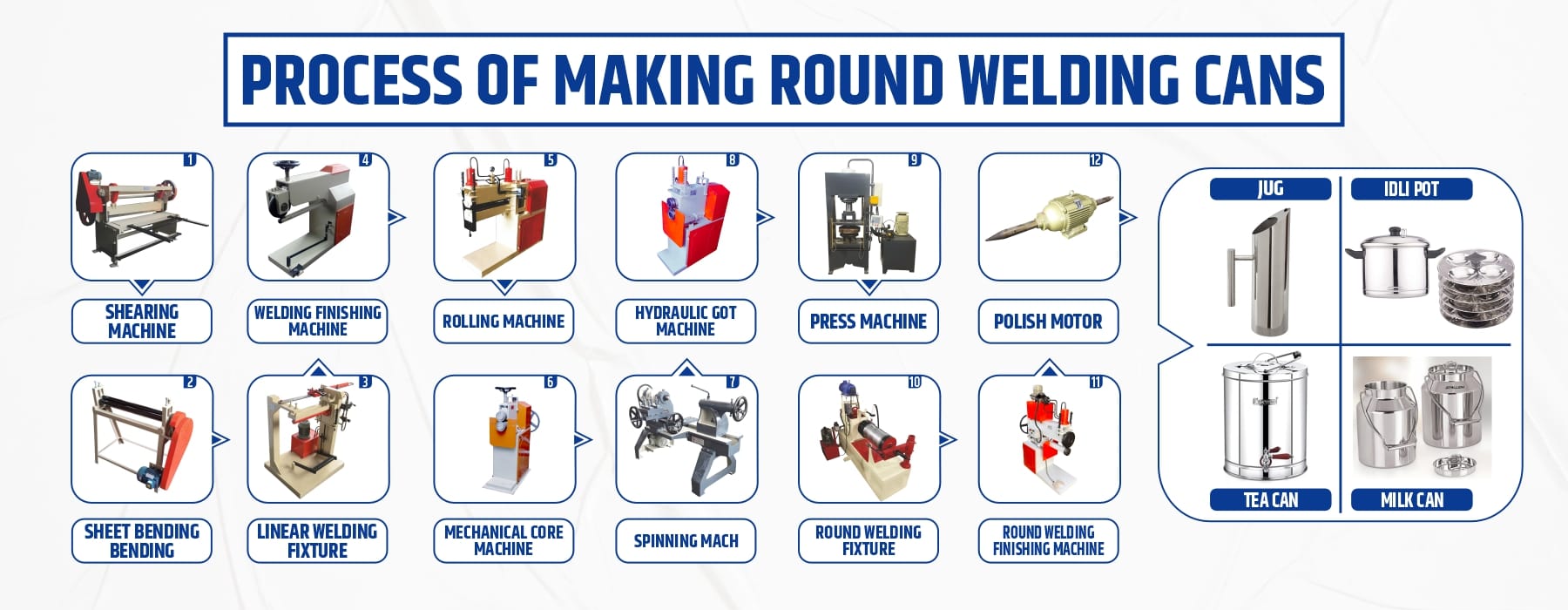

Round Welding Cans Making Plant From Start to Finish

At Yashwant Industries, we specialize in designing and manufacturing Round Welding Cans Making Plants that deliver precision-engineered solutions for the production of high-quality, durable cans. From cutting-edge machinery to seamless integration of the entire process, our plants are designed to optimize productivity and ensure top-tier quality.

Our plants cater to industries such as food packaging, chemical storage, pharmaceutical packaging, and household containers, providing a reliable solution for your production needs.

Cuts large metal sheets to the required size. Ensures precision and reduces material wastage.

Sheet Bending Machine

Bends the metal sheets to form the cylindrical structure. Prepares the base shape for further processing.

Learn More

Joins the bent sheets with a strong weld. Ensures durability and seamless structure.

Smooths out the weld joints. Improves structural integrity and appearance.

Further rolls the welded structure into a perfect cylindrical shape. Ensures uniformity and correct dimensions.

Strengthens the can’s core. Provides structural support and durability.

Spinning Machine

Shapes the can’s bottom and top edges. Enhances precision and strengthens the can’s form.

Learn More

Applies high-pressure shaping to form intricate details. Ensures consistency in production.

Presses and forms additional structural elements. Shapes the can’s final components.

Ensures round components are securely welded. Maintains uniform shape and structure.

Round Welding Finishing Machine

Refines the final welded joints. Enhances strength and aesthetics.

Learn More

Polishes the final product for a shiny and smooth finish. Prepares the can for commercial use.

Provides a smooth surface finish by passing the material through hydraulic rollers. Improves material strength and enhances its visual appeal.

Shapes the container’s edge with precision, preparing it for the next stage of production. Adds structural rigidity to the container.

Small Hydraulic GOT Machine

Processes smaller containers or detailed features with hydraulic precision. Delivers consistent results for intricate container designs.

Learn More

Shapes the container by spinning and forming it to the desired specifications. Ideal for creating smooth, uniform cylindrical shapes.