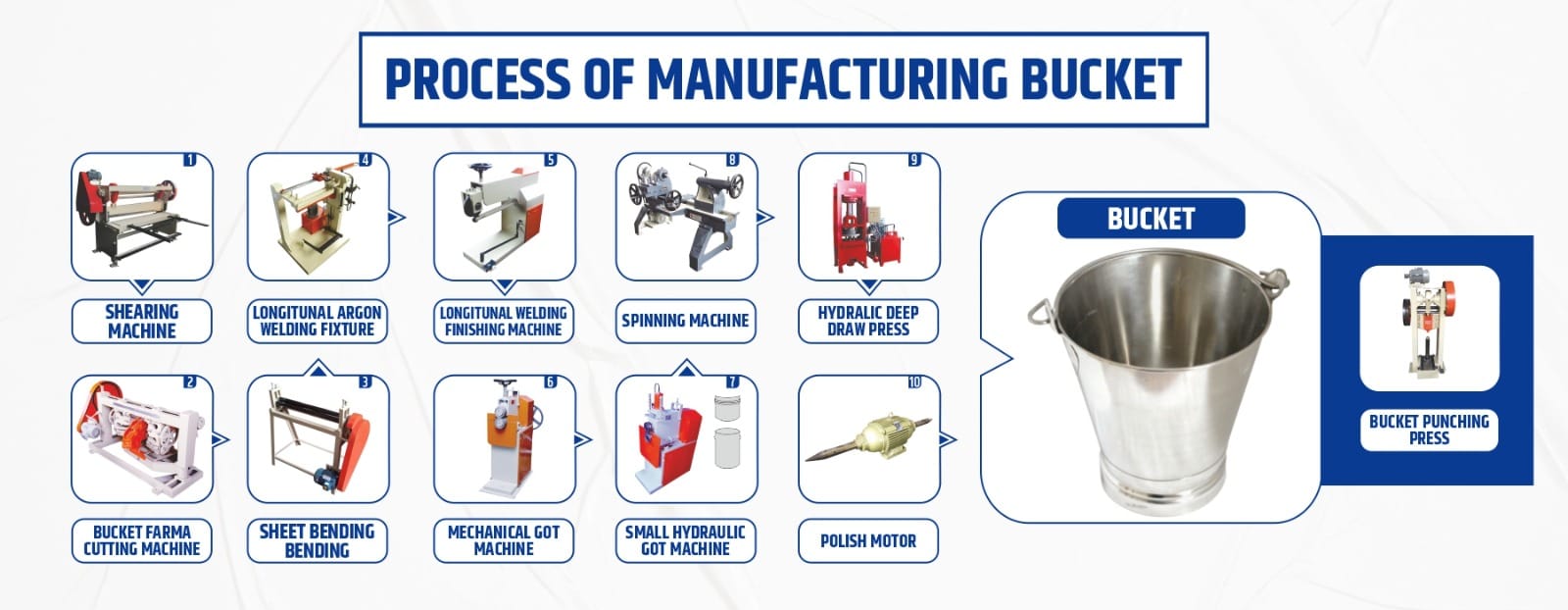

SS Bucket Balti Manufacturing Plant From Start to Finish

We follow a streamlined and precise process to SS Bucket Balti Manufacturing Plant in India, high-quality canisters that meet global standards. Each step in our process is designed to ensure durability, efficiency, and superior craftsmanship.

The process starts with cutting stainless steel sheets into required sizes using a Shearing Machine. This ensures precise and uniform dimensions for further processing.

Bucket Frame Cutting Machine

A Bucket Frame Cutting Machine is used to cut the sheets into the necessary shapes and sizes required for forming the bucket.

Learn More

The cut sheets are bent into a cylindrical shape using a Sheet Bending Machine. This step ensures that the bucket takes its initial form.

The bent sheets are joined together using a Longitudinal Argon Welding Fixture, which provides a strong and seamless weld along the length of the bucket.

A Longitudinal Welding Finishing Machine is used to smoothen and refine the welded joints, ensuring a clean and polished appearance.

The bottom of the bucket is shaped and strengthened using a Mechanical Got Machine, which ensures durability and stability.

Small Hydraulic GOT Machine

A Small Hydraulic Got Machine is used to press and attach the bottom of the bucket, ensuring a secure fit and long-lasting performance.

Learn More

A Spinning Machine is used to refine the edges, improve the structure, and enhance the final shape of the bucket. This step increases strength and ensures smooth finishing.

A Hydraulic Deep Draw Press is used to further shape the bucket, giving it its final depth and structure.

The bucket is polished using a Polish Motor to achieve a smooth, shiny, and corrosion-resistant surface.

Bucket Punching Process

Finally, handles or other attachments are added using a Bucket Punching Press, making the bucket fully functional and ready for use.